Discipline Engineering

Share

We have in-house discipline engineering covering all the key skills needed to meet client needs in high hazard process industries either delivering full projects or specific design studies.

We use industry recognised design software and our quality procedures are ISO9001 accredited.

- Process

- Safety

- Control and Instrumentation

- Electrical

- Mechanical

- Rotating Equipment

- Piping

- Structural

- Civil

- Cost Engineering & Procurement

- Construction & Commissioning Support

In more detail..

Process

- Process design development and technology selection

- Process scale-up and commercialisation

- Steady State and Dynamic simulation and modelling

- Plant uprating and de-bottlenecking

- Troubleshooting

- Relief and Blowdown studies

- Hydraulic analysis

- Multiphase pipeline flow modelling

Technical Safety Services

- Hazard Identification and Quantitative Risk Assessment

- Atex / DSEAR Risk Assessment Studies

- Hazardous Area Classification

- Consequence Analysis and Dispersion Modelling

- HAZID/ HAZOP Studies including chairmanship

- LOPA and SIL studies including chairmanship

- Bow-tie analysis

- Process safety time assessment

- Emergency shutdown system design/ philosophy

- Trip requirement and availability calculation

- Cause & Effects studies

- HSE philosophies, including COMAH case

- Flare and Vent and Disposal systems design, analysis and modelling

- Explosion, Fire protection and fire-fighting systems

- Fire & gas detection

- Escape routes and temporary refuges

- Safety MOC reviews

- Safety critical elements identification

- Alarm Management/ Rationalisation

- Asset integrity (ageing plant) review

- Dropped objects review

- Occupied Building risk assessments

- HP/ LP interface review

- Effluents and emissions analysis

- Human factors assessment

- BAT assessment

- COMAH and support to planning applications

- Environmental assessment and support to environmental permits

- Hazardous substance planning review

Control and Instrumentation

- DCS & ESD Control System design/ modifications/ Obsolescence studies

- Control algorithm, System architecture & logic flow diagrams

- Control room HMI/ upgrade

- Instrumentation design

- Functional Safety Management

- IEC 61508/61511, SIL rated system design

- TUV accredited engineers

- Design surveys, compliance to IEC60079 (explosive atmospheres)

- Measurement and metering systems

- Alarm Management

- Cyber Security

- Site security access, CCTV

- Package FAT and SAT testing and inspection

Electrical

- Electrical distribution obsolescence and upgrade

- Power systems analysis

- Full Electrical Network Analysis and electrical systems modelling

- HV and LV distribution design

- Load and fault analysis Full synchronisation, load sharing and load shedding schemes for power generation

- Motor Control Centre (MCC)/ Local Equipment Room (LER) design

- UPS, Power backup and Blackstart

- Cable calculations

- Electrical protection calculations

- Network analysis and modelling

- Earthing systems

- Lighting and emergency lighting design

- Lightning protection design

- Hazardous area design expertise

- Package FAT and SAT testing, inspection and commissioning

- Site Certification Evaluation & Compliance

- ATEX Compliance Evaluations

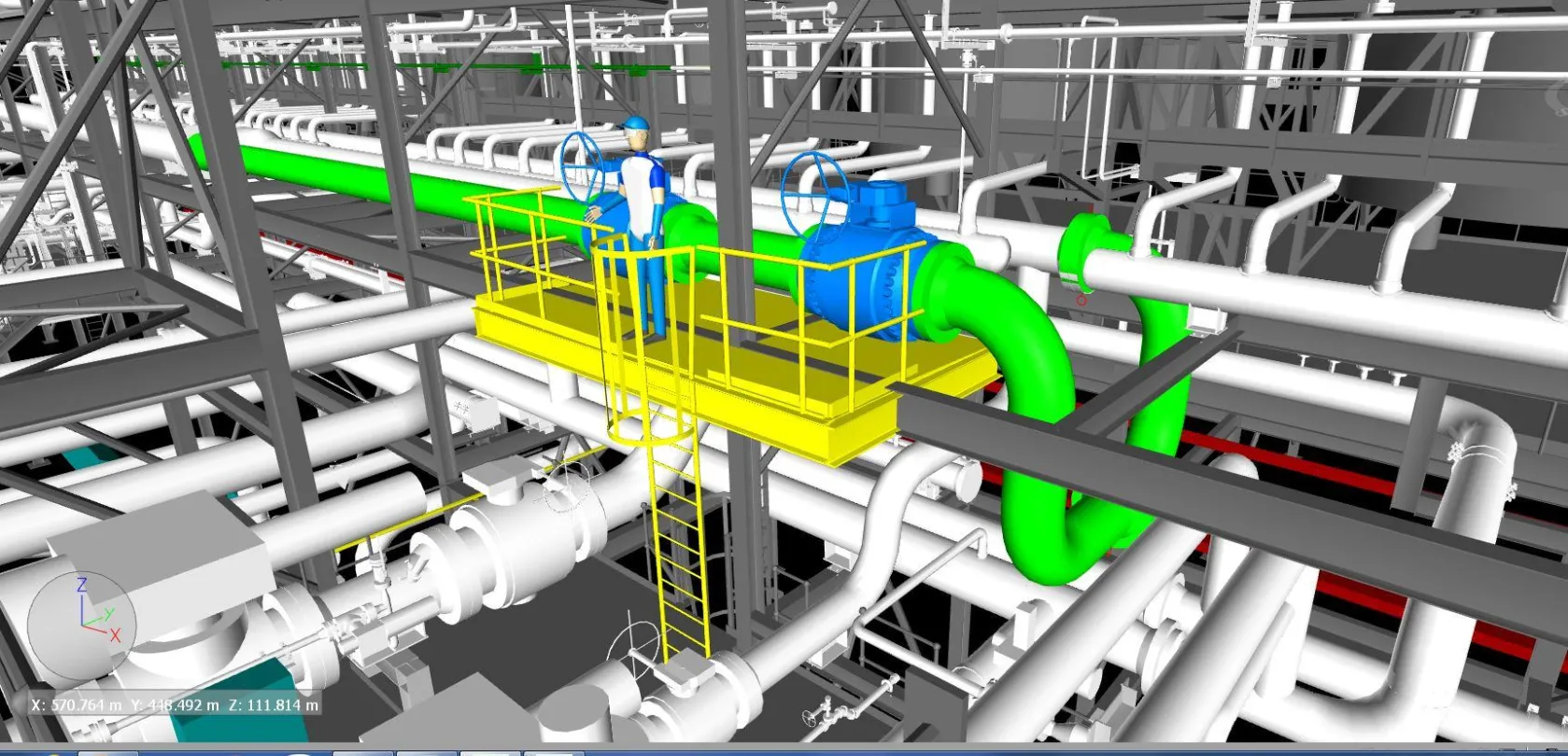

Mechanical and Piping

- Equipment specification and selection

- Static equipment specialists – pressure vessels, heat exchangers, etc

- Utility systems: air, nitrogen, refrigeration

- Equipment package management

- Piping design, fatigue analysis, supports and layout, GA’s, Isometric drawings

- Dynamic Stress analysis (FEA & CFD studies)

- PED consultancy

- Mechanical condition assessment

- Materials selection

- 3D modelling and design

- Corrosion assessment

- Noise assessment

- Vibration analysis

- Fitness for Service (FFS) studies, inspection and analysis

- Reliability, availability, maintainability (RAM) studies.

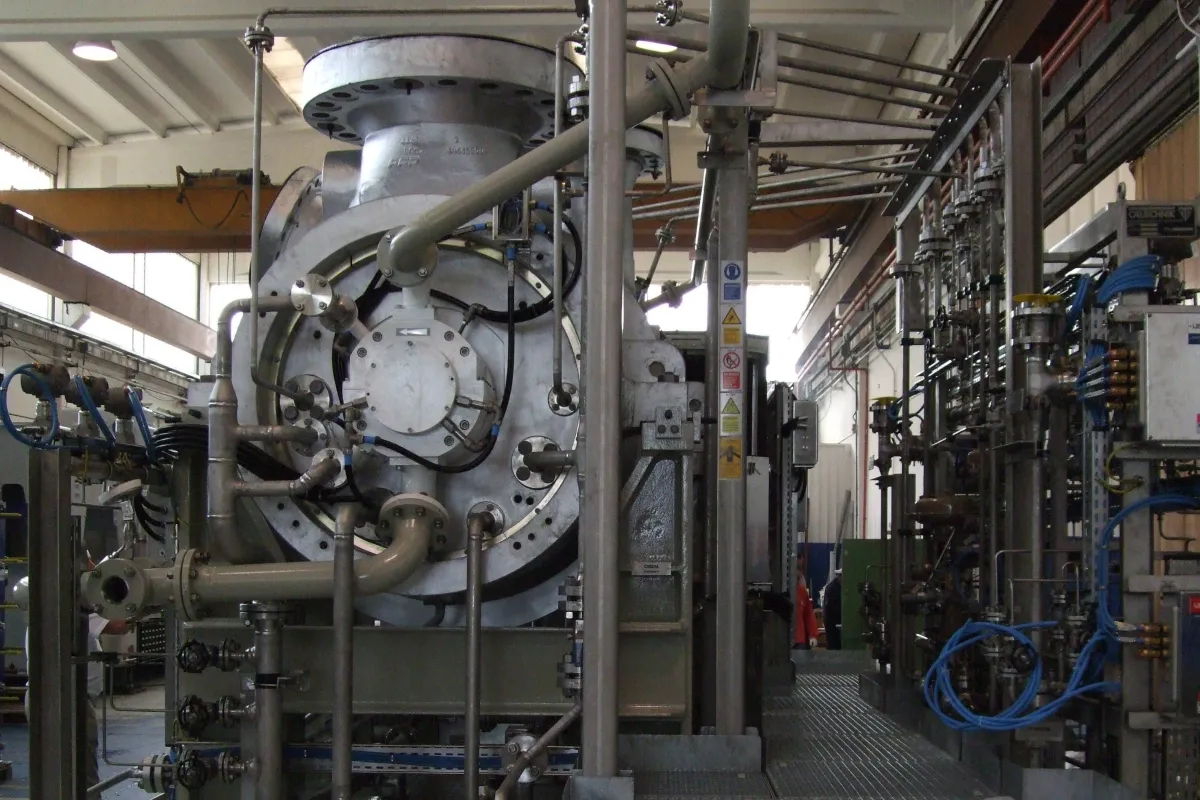

Rotating Equipment

- Rotating equipment selection and specification – specialist pumps, compression systems and drivers – gas turbines and electric

- Materials of construction

- Inspection, test and commissioning support

- Constructability and maintainability reviews

- Vendor interface and Technical Bid Evaluations

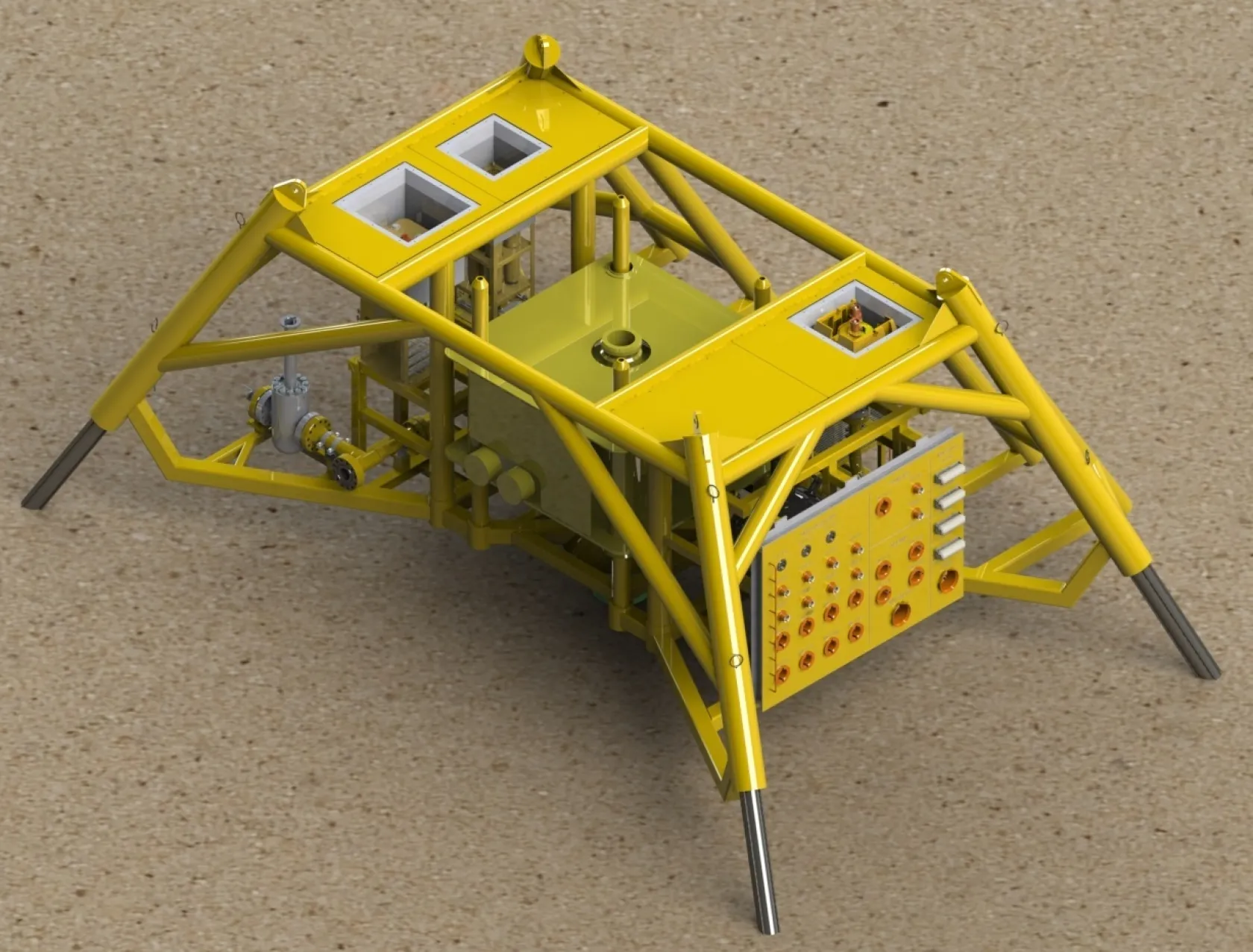

Structural

- Structural modelling and load analysis

- Dynamic loading analysis

- Structural design: superstructure and foundations

- Lifting and handling

- Strengthening of existing structures and foundations

- Steelwork fabrication detailing, including connection design calculations

Civil

- Design: bunds, foundations, roads, paving and drainage

- Reinforced concrete detailing

Cost Engineering & Procurement

- Development of project cost estimate (AACE, CII PDRI)

- Equipment enquiries

- Budget costs to buying, expediting and material controls

- Commercial bid evaluations

Construction & Commissioning Support

- Construction management?

- System Commissioning Logic

- System Descriptions

- System/Item Test Documentation

- Factory and Site Acceptances

- Commissioning Procedures

- Commissioning Management

- Training Plan

- Comprehensive Handover Plan

- Preparation and Update of Operating Procedures

- Update of Maintenance Management Systems

Next: Recruitment