LNG Offloading Terminal Pre-FEED

IM Skaugen (IMS), Middle East in LNG and LPG, Design Development & Implementation, PreFEED

Share

IM Skaugen (IMS) already used their smaller Multigas Ships for Liquid Petroleum Gas (LPG) and wanted to also enter the Liquified Natural Gas business (LNG).

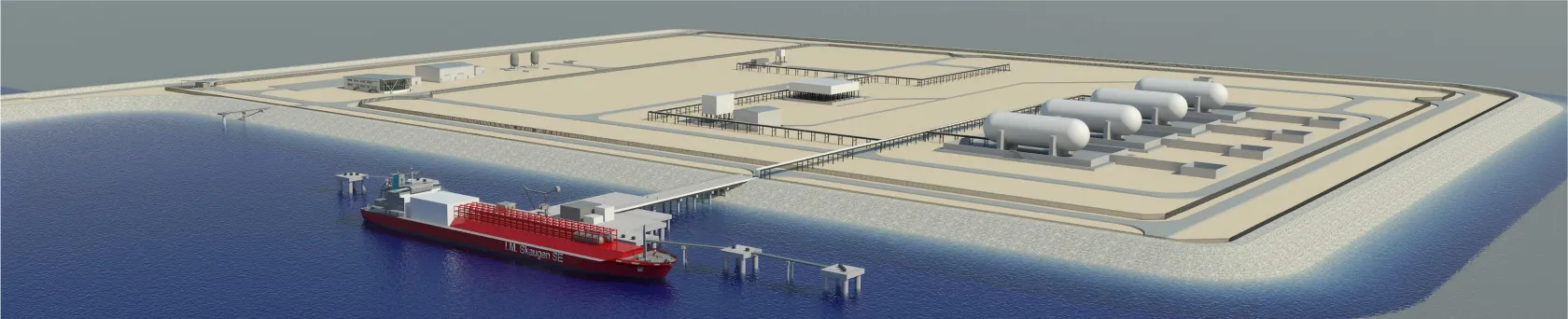

An opportunity for IMS arose when the Bahrain Petroleum Company Bapco required a small land-based LNG storage facility sited on reclaimed land. The IMS philosophy to minimise land storage was to locate a storage ship offshore and then LNG could then be transferred between the two.

OSL designed the terminal so that IMS were able to present a technical solution together with a commercial proposal for the terminal build and operation. A joint venture bid arose with OSL to design the terminal to minimise the reclaimed land.

Project Overview

This project included design of an LNG receiving facility, storage facility, regasification facility, boil-off gas handling and gas export.

OSL was involved in the specification of the land reclamation, the design of site facilities and buildings, as well as utilities such as power generation, cooling water and fire water. Safety aspects were an important part of the design, including ensuring that containment and spillage segregation systems were included.

Process simulation models were created during the design. Also 3D computer graphic models were prepared allowing the visualisation of the proposed terminal on the reclaimed land.

Key Aspects of Delivery

- The novel nature of this project required OSL to think outside the box to overcome problems, such as the use of bullet storage tanks.

- Clever thinking was essential to ensure the novel concept could be actualised and keep the overall cost to a minimum and the project within the required timescale.

- Design work had to meet a strict deadline set by the end client.

Clever Thinking®

The system capacity was designed in such a way so as to allow for easy expansion without loss of production. This included a jetty design which could be easily converted to berth much larger ships with the addition of a single central loading arm structure. The storage system was designed to shorten the construction time of the facility by using the same tank design as those in the ship. This allowed the tanks to be fabricated offsite in parallel to the civils works. This was much quicker than the more traditional flat bottomed type. The tank design was modular and much cheaper giving an advantage on flexibility and overall capex.

Benefits to Client

- A well compiled and supported bid covering all aspects of the terminal design and operation

- A shorter project timescale

- Reduced cost for main equipment

- A flexible and expandable design

- Excellent organisation throughout project

- Timescale and cost were adhered to and kept to a minimum

- A highly skilled and capable team.

Latest Case Studies

LNG Offloading Terminal Pre-FEED

IM Skaugen (IMS)

Centrica Storage - York Compression FEED

Centrica Storage

LAPS Compression Feasibility Study

A Gas Producer

LPG FEED project

Independent Oil and Gas Company

Pyrolysis Wax Plant Modification Design FEED

Trifol