Centrica Storage - York Compression FEED

in Natural Gas Processing, Design Development & Implementation, PreFEED

Share

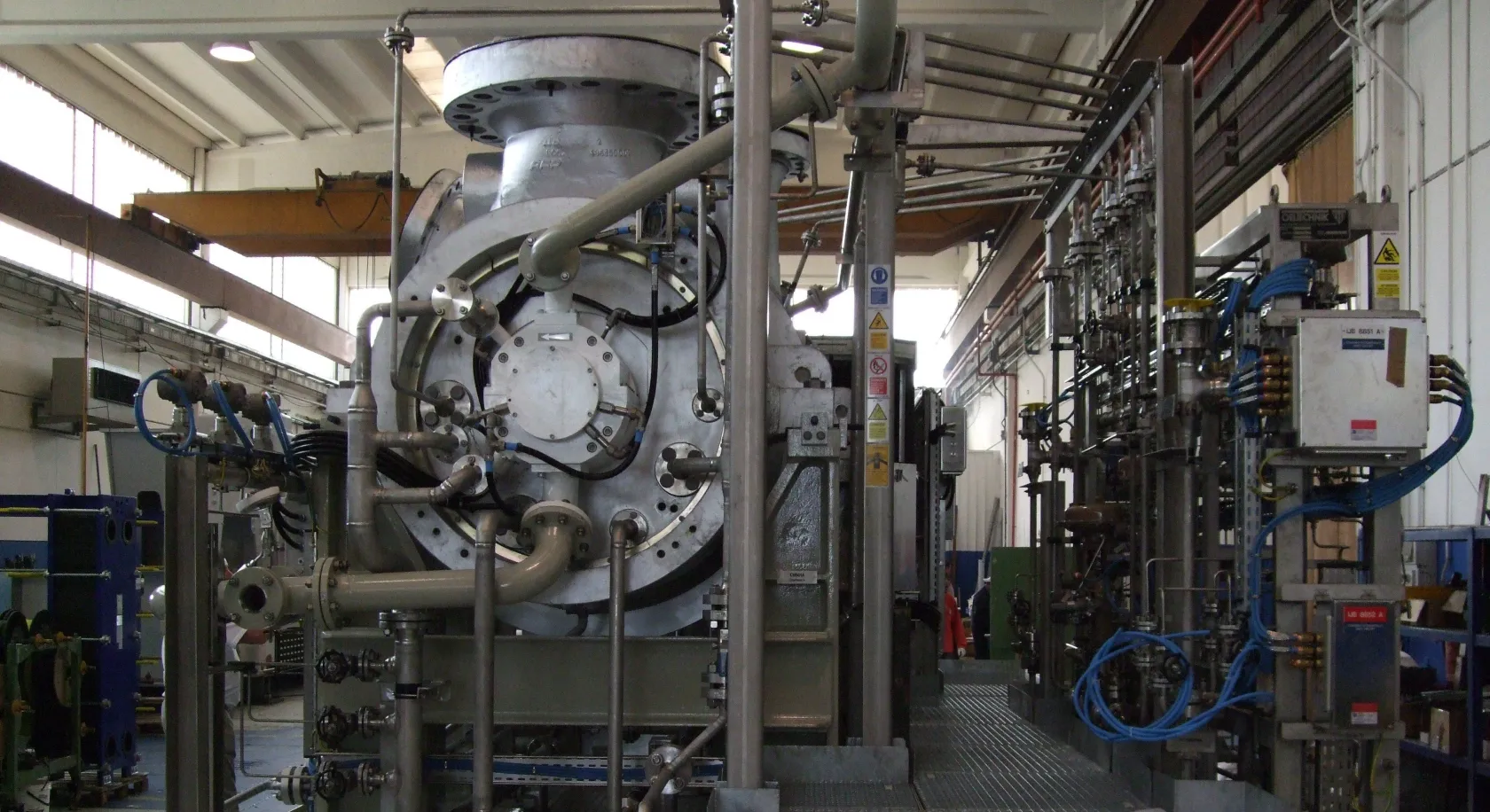

OSL completed a pre-FEED study to design a new onshore compression system to increase the produced natural gas volumes from a UK gas field.

Following the pre-FEED study, OSL conducted a FEED study for the client, with a level of detail that allowed a project cost estimate of +/-15% to be produced. This in turn assisted the client to secure the Final Investment Decision (FID) for execution and implementation to meet the project’s time constraint.

Project Overview

An opportunity was identified to increase future recoverable reserves and increase the gas production rate from a UK field by adding onshore compression. The installation of the new compression system would enable a decrease in the operating pressure of the offshore equipment, subsea pipeline and inlet facilities. This increased the sweep velocity in the pipeline would aid with pipeline liquid management whilst allowing lower pressure fields to be recovered.

The FEED study was developed to determine whether this opportunity met the client’s technical and economic criteria for implementation. Also, long lead items and their cost were identified which allowed early placement of orders immediately after the FID to reduce the project schedule.

Key Aspects of OSL Delivery

- Evaluation of compressor technologies (conventional vs hermetically sealed)

- Compressor driver selection – GT or Electric drive

- Provision of full technical and commercial evaluation on compressor bids

- Safety assessments including HAZID/ENVID, HAZOP and LOPA studies

- Plant 3D model showing the integration of the compression system within the existing terminal

- Constructability and maintainability reviews

- ASTM E2516 Class II cost estimate (+/- 15%)

- Level 3 project schedule

- Long lead item identification

- FEED package

Clever Thinking®

- A clever thinking session was conducted to identify potential solutions so that the project targets could be met.

- A commitment to deliver the FEED on time at a maximum economic value for the client was significantly important for the project as this allowed the FID to be achieved on target.

- Early identification and development of long lead items also meant orders for these could be placed immediately after the FID.

- Clear scope and good communication were highlighted and implemented as the working basis of the team. This resulted in success in delivering the project on time and within the budget.

Benefits to Client

- Enhanced gas production rate

- Extended field life

- Enhanced liquid management in the pipeline to the terminal and reduced frequency of pigging operations

- Cost estimate and schedule enabled the FID

Latest Case Studies

LNG Offloading Terminal Pre-FEED

IM Skaugen (IMS)

Centrica Storage - York Compression FEED

Centrica Storage

LAPS Compression Feasibility Study

A Gas Producer

LPG FEED project

Independent Oil and Gas Company

Pyrolysis Wax Plant Modification Design FEED

Trifol