Design Development and Implementation

Share

Third Party Development/ R&D Commercialisation

OSL’s Clever Thinking ethos and adaptability is well suited to supporting companies develop commercial designs based on novel processes. Companies that have developed a novel process and brought it to bench or pilot scale can often struggle progress the Technology Readiness Level, and to scale up to a semi-/ commercial scale plant with all the necessary balance of plant infrastructure to support operation such as power supply, utilities, feedstock and product storage and handling. A core technology relies on much other support equipment. OSL’s team have the experience to work closely with you to develop a robust design and costing and to prepare an investment case.

Concept Design

Concept and Feasibility design studies are at the forefront of OSL core skills. Our multi-discipline team of process, safety, mechanical, control, electrical, civil and structural engineers are experienced at working closely and proactively with our clients to bridge the path between an investment idea and a budget costed project (ca. -30%/ +50%) that is ready to take forward into FEED. Concept studies enable our clients to make informed decisions; often saving themselves and stakeholders’ time, money and effort throughout the life of a project.

At the concept stage, various options are evaluated from a technical, economic and safety perspective. The concept design is where OSL can really apply its ‘Clever Thinking®’ philosophy and experience across multiple industry sectors and add value for our clients. Our approach allows options to be assessed and evaluated from a technical, economic and safety perspective, and compared in a structured and a constructive session of generating solutions, deciding a course of action and implementing and evaluating those solutions. The various drivers for the project are featured in the evaluation as well as several sensitivities carried out to fully understand all underlying risks.

Some of the key objectives that OSL employ when framing concept studies are:

- Understanding the client’s key business drivers and the underlying critical success factors.

- Assessing the strategic, economical, operational and social risks associated with the project in order to evaluate the entire project lifecycle

- Understanding the key technologies (established and/or novel) involved in order to perform a cost/benefit analysis.

- Assessing the technical requirements of the project and derive an understanding of the key challenges from a resource to operational basis.

At the feasibility/Pre-FEED stage, OSL will progress the project to add more definition in order to develop the key process, control and safety philosophy requirements. The feasibility stage of the project can include:

- Process modelling

- Selection of a Process Scheme

- Process Justification

- Selection of Major Equipment

- Initial liaison with vendors for long lead items in particular

OSL has performed a portfolio of Concept and Feasibility studies that have enabled our clients to make informed investment decisions and turn an idea into commercial reality.

FEED Design

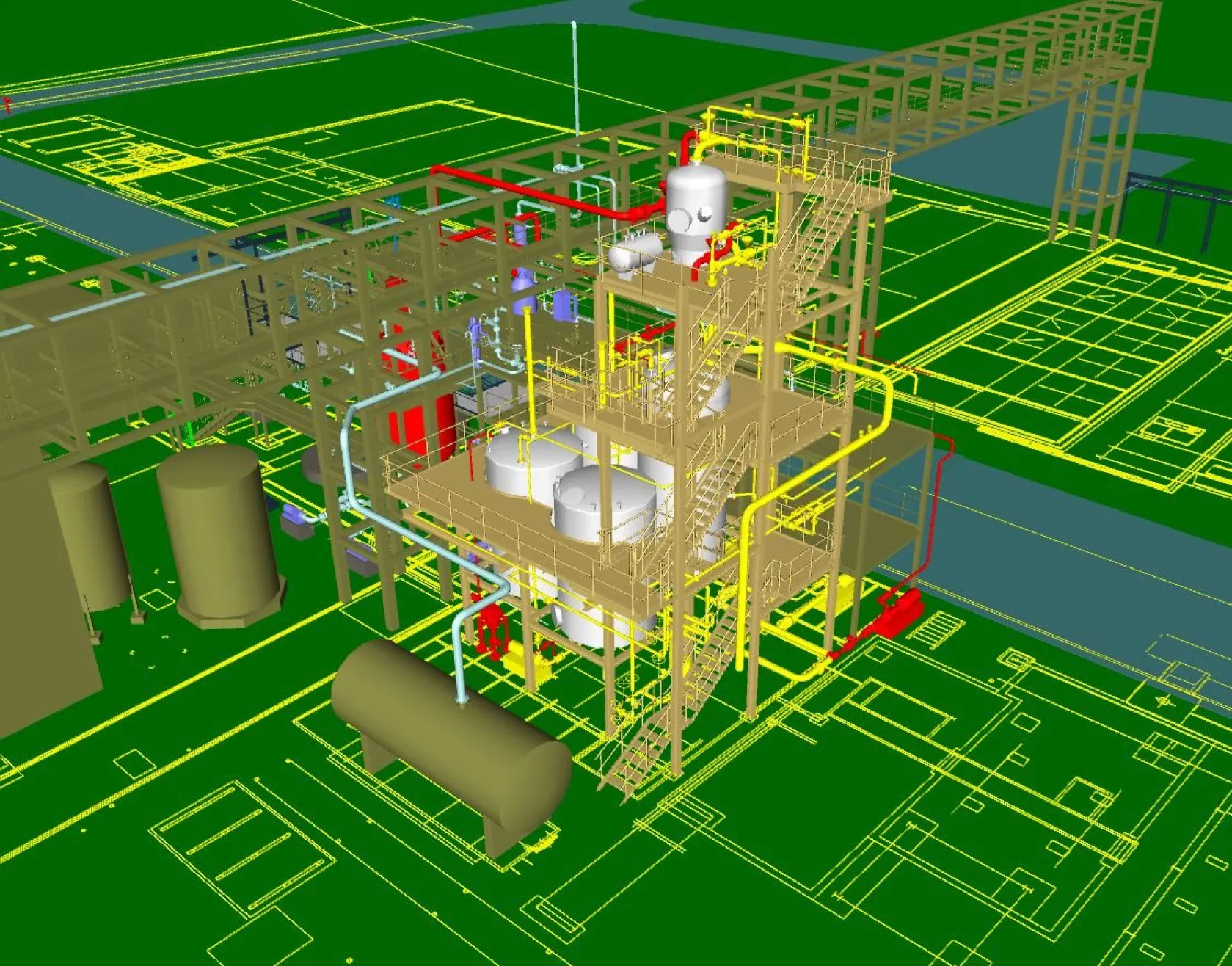

The outcome of the FEED phase is a design maturity and cost confidence to support the investment decision leading to project sanction.

OSL has executed numerous FEED projects for major national and international companies and fully understand the importance of reflecting client’s intentions and project specific requirements at the FEED stage. OSL work closely with the client team to provide design definition to an extent that meets the client’s design/ cost risk criteria prior to advancing to the detailed design and implementation stages.

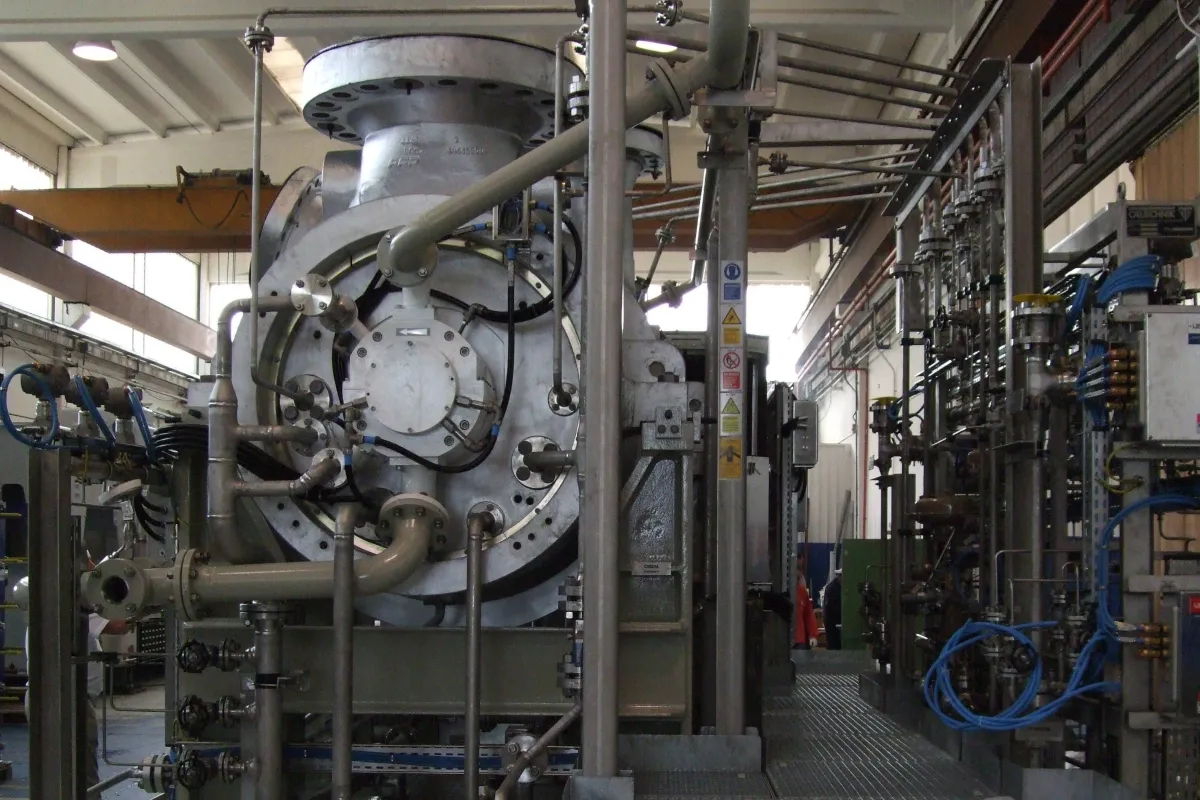

Detailed Design / EPCm

The OSL team have the systems, software tools and resources to execute detailed design and / or fully take on the EPCm delivery for a project. In this phase, the design of each aspect is developed to ensure that it complies with design standards and requirements including PED/PER and CDM; and incorporates all safety, constructability, operability and maintainability needs.

The design will include the preparation of the technical information for procurement of equipment, packages, piping, valves, instrumentation, control, safety and power systems. In this phase OSL receive vendor information specific to the items procured and incorporate them effectively into the full installation specification.

Our multi-discipline engineering, procurement and construction management resources are used to working with client teams, equipment vendors and construction companies to successfully manage the overall delivery of a project. Our skilled engineers can also support with commissioning plant.

Project Management

OSL’s Project Management team have the expertise and tools to effectively manage and report on project delivery. We offer standard dashboard reporting of KPI’s but understand that clients may have specific needs and therefore we will adapt reports to suit. Our approach is very much to engage and work with you transparently so that you have a full understanding of project progress.

Project plans are developed to track progress according to the project stage. OSL will identify the critical project path and can monitor and manage projects risks and keep an up to date Risk Register. We undertake regular risk reviews to update the cost and schedule status. Using our own proprietary forecast tools, we build the risk model and link the project risk register to critical and subcritical tasks. The ongoing review of risks allows the dynamics of the project risks to be understood, enabling the project team to implement appropriate mitigation measures and give confidence to meet the project deadlines and cost.

Our team can provide CDM advice and support by undertaking Principal Designer (PD) and Principal Contractor (PC) roles where required, together with HSSEQ input during the project development, planning and execution phases.

Next: Engineering Consultancy