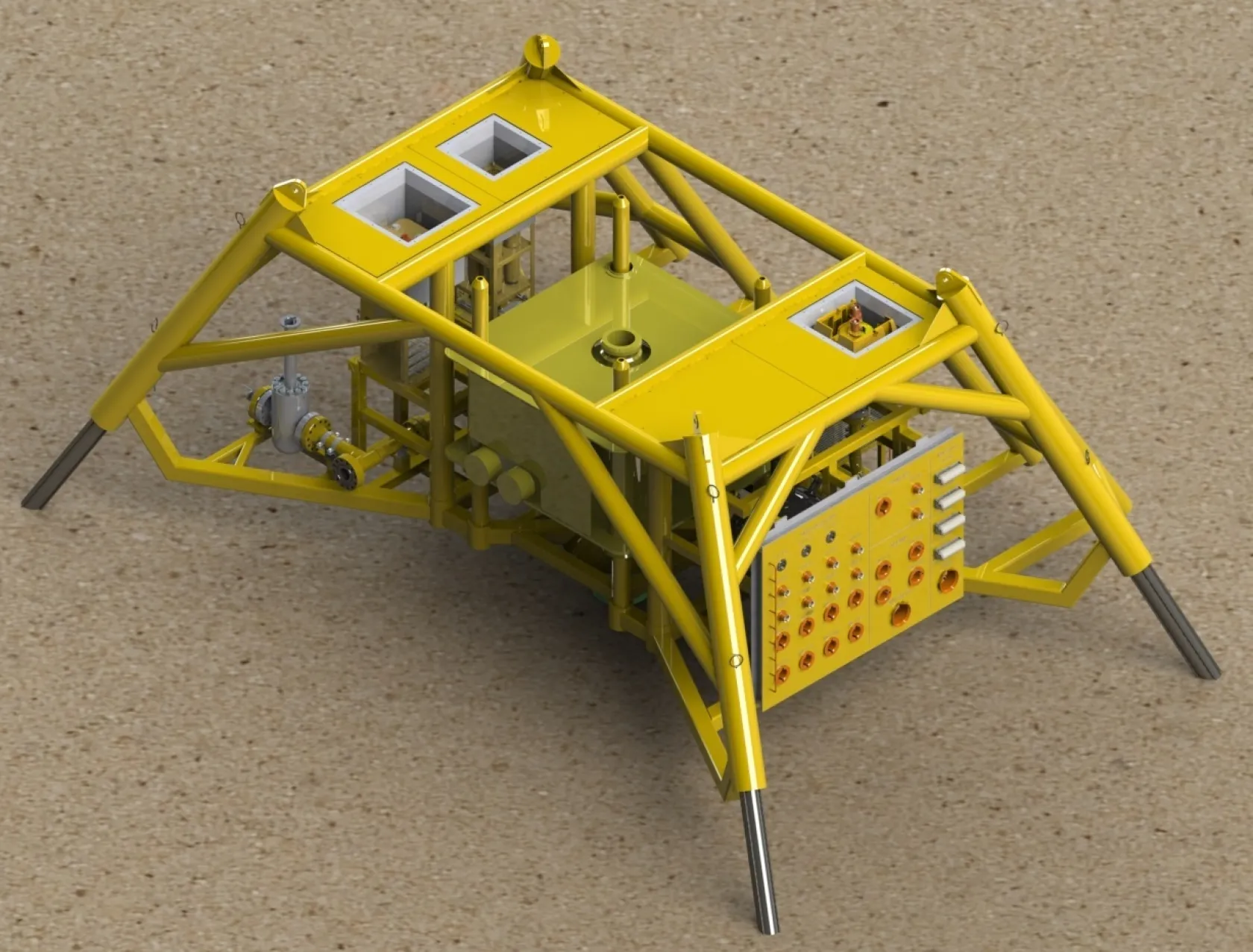

SubSea Cyclone Separator System

in Natural Gas Processing, Design Development & Implementation, Detailed Design

Share

In 2017 the OGA estimated that there were 3.8 trillion cubic feet (Tcf) of remaining gas accessible within the UK Southern North Sea. A proportion of this gas was expected to be in economically marginal smaller reservoirs and also tight gas reservoirs. The OGA supported a design study collaboration between Spirit Energy Ltd and OSL to develop a commercially viable technology for recovering gas from tight, fracked subsea gas fields such as those encountered in the SNS.

Project Overview

OSL and Spirit Energy in partnership, carried out a conceptual study to investigate technologies to recover tight gas and transport it through a subsea pipeline to an adjacent offshore platform or subsea pipeline network. One of the challenges of recovering gas from tight fields is the need to manage potential produced sand and proppant that can appear in the gas. The aim of the study was to develop a robust and simple technical solution that allows sand and proppant separation to be carried out subsea and avoid the risk of pipeline blockage.

Key Aspects of the Delivery

The design scope performed by OSL included:

1. Conceptual consideration of:

- The subsea facility process design options.

- The host platform process design requirements.

- Ship/ROV (Remote Operated Vehicle) design requirements.

- The assessment of possible engineering measures needed to mitigate or control hazards and operational constraints.

2. Comparative development costs and schedule

3. Safety assessments including HAZOP and LOPA studies.

OSL and Spirit successfully developed the detailed design (ready for fabrication) for a subsea separation unit which can be operated remotely. The design approach enables the tie back of produced gas to either a host platform or pipeline. The solution incorporates an ROV and ship-based attachable removal system for periodic sand removal for onshore treatment and disposal.

Clever Thinking®

The design approach makes use of available proven components integrated into a novel compact assembly that enables continuous production and batchwise removal of any sand and proppant.

Benefits to the Client

The benefit to the client was OSL’s ability to provide technical and safety perspective to progress the subsea design. The design is a viable and highly cost-effective solution relative to alternative production options that is attractive as a solution for undertaking tight gas developments within the SNS or similar environments

Latest Case Studies

LNG Offloading Terminal Pre-FEED

IM Skaugen (IMS)

Centrica Storage - York Compression FEED

Centrica Storage

LAPS Compression Feasibility Study

A Gas Producer

LPG FEED project

Independent Oil and Gas Company

Pyrolysis Wax Plant Modification Design FEED

Trifol